“According to local press reports, the Miike dye works of the Mitsui Bussan Kaisha are to undertake the manufacture of salicylic acid on a large scale in order to supply all domestic requirements of this chemical.

“Hitherto nearly half of the salicylic acid used in Japan has been imported. Germany was for a time the principal source, but the largest quantities are now being imported from the United States, followed by Great Britain, Germany and France in the order named.

“… [W]ith the completion of a special plant for the manufacture of salicylic acid, the Miike dye works will be able to produce over 300,000 pounds annually. This with other sources within Japan should make that nation independent of foreign countries.

“The plant is to be completed in November, 1927, and will cover a ground area of over 6,000 square feet.”

– “New Salicylic Acid Factory in Japan”, by U.S. Consul (Nagasaki) H.B. Hitchcock, Chemicals, November 28, 1927

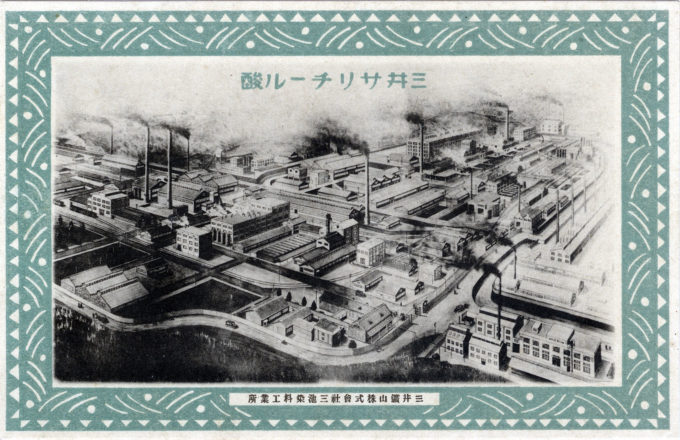

“Mitsui Salicylic Acid”, Miike Dye Works, Mitsui Mining Co., Omuta, Kyushu, c. 1928. The plant opened in 1927 to manufacture salicylic acid, an organic compound used to make medicated topical solutions with which to treat or prevent acne and other skin conditions – warts, psoriasis, calluses, corns. The chemical compound also had uses as a food preservative, a bactericide, and an antiseptic.

See also:

Mitsui Bank, Nihonbashi, c. 1905.

“According to a representative of the Mitsui Mining Co., as reported in the newspapers, all the by-products of the Government Iron Works, the Mitsui Mining Co., the Mitsui Bishi Co., the Tokyo Gas Co., the Osaka Gas Co., and other factories are being fully used.

“… Aniline salt and induline are already being marketed by the Tokyo Gas Co. The Mitsui Mining Co. has succeeded in producing a variety of dyes from coal tar produced by its works at Miike. A month hence the company hopes to extend the list of its products so as to include additional derivatives of benzol, carbolic acid, salicylic acid, and picric acid.”

– “Dyestuff Industry Developing in Japan”, by Consul General (Yokohama) George H. Scidmore, Paint, Oil and Drug Review, June 28, 1916