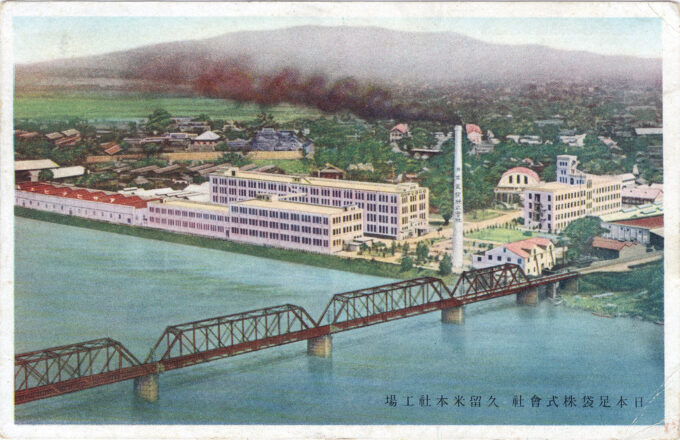

Nippon Tabi Co. Ltd., Kurume, Fukuoka, c. 1930, predecessor of Bridgestone Tire. Nippon Tabi got its start in 1918 by manufacturing workers’ footwear called jika tabi, rubber-soled split-toe boots, before using its rubber manufacturing technology to enter the domestic automobile tire market. Bridgestone was named for its founder, Ishibashi Shojiro (‘Ishibashi’ means ‘stone bridge’) who had also first established Nippon Tabi Co. in 1918. In 1937, Bridgestone would move its manufacturing base from Kurume to Tokyo.

See also:

Nippon Ford Assembly Plant, Yokohama, c. 1930.

“In 1918, Shojiro Ishibashi established Nippon Tabi Co., Ltd., turning it from a small family business into a more organized, larger incorporated business. Ishibashi abolished the firm’s original custom-made production business model in favor of manufacturing and selling only one product: tabi (Japanese split-toed socks).

“In 1921, Nippon Tabi began developing an advanced form of tabi called jika tabi [lit. ‘tabi that touch the ground’]. Though tabi could be worn with traditional thonged footwear such as geta and zōri for outdoor wear, jika-tabi were expressly designed and made to be worn alone in the outdoors, resembling boots that reached roughly mid-calf. Jika tabi were made of a heavy cloth pasted with a rubber sole pasted on the bottom for outdoor wear and work.

“Before this time, ordinary workers used waraji (straw sandals). Workers wore them on bare feet, and were often injured by nails and other materials on construction sites. Waraji also were not durable. The typical worker wore through 18 pair of waraji each year, and replacing each pair cost them ¥1.50 (about ¥18 per year). The average laborer in 1921 earned ¥1 per day.

“The price of one pair of Nippon Tabi’s jika tabi was 1.50 yen. The useful life of a jika tabi was about half a year, so the annual cost of footwear using jika tabi was 3 yen. Compared to 18 yen per year for waraji, the cost was reduced by five-sixths. Consumers were very pleased with the emergence of jika tabi which was both economical and safe. In January 1923, the production of jika tabi began at the rate of 1,000 pairs per day but, by the end of the year in December, production had increased dramatically to 10,000 pairs per day.

“Nippon Tabi grew its core jika tabi technologies into [making other] rubber processing improvements. Ishibashi’s next company goal then became to produce automobile tires — a logical expansion of business for a rubber-based business — a manufacturing sector in Japan that had no wholly-owned Japanese companies in competition [only joint-ventures, e.g. Dunlop Far East Co., Ltd.].

“In 1929, Ishibashi ordered a tire manufacturing machine with a production capacity of 300 tires a day, and set up a small tire factory in a corner of the Kurume factory of Nippon Tabi.

“… In 1931, Bridgestone Tire Co., Ltd. was established, and Shojiro Ishibashi became president. To compete with the overwhelming advantages that the foreign joint-ventures enjoyed selling tires in Japan, Bridgestone Tire offered its customers an unconditional replacement guarantee. There was some customer abuse of this system and the losses to the company were not small, but Ishibashi endured.

“The entry of Bridgestone into the domestic market immediately forced the foreign joint-venture firms into competition, resulting in pricing benefits for customers across the tire market.

“Bridgestone’s automobile tires were recognized in 1931 as ‘excellent domestic products’ by the Ministry of Commerce and Industry as well as receiving critical and more practical endorsements the same year from Nippon Ford, Nippon General Motors, and Chrysler who each began installing Bridgestone tires as ‘factory-original’ parts onto their domestically-produced automobiles.”

– Shojiro Ishibashi: Pioneer of Automobile Tire Manufacturing in Japan, by Masaatsu Takehara & Naoya Hasegawa, April 2020